Если вы планируете приобрести индукционный паяльник в 2026 году, вам следует обратить внимание на модели от Canroon, Ultraflex, Fusion Inc., Radyne и Siemens. Эти бренды предлагают машины с интеллектуальным управлением. Они также используют энергосберегающие технологии. Настройки мощности можно изменять. Некоторые машины легко переносить для работы в полевых условиях. Выберите подходящую машину для ваших нужд. В таблице вы найдете важную информацию:

- Убедитесь, что мощности станка достаточно для обработки ваших металлов.

- Обратите внимание на удобные в использовании элементы управления и функции безопасности.

- Если вы работаете на открытом воздухе, мобильность очень полезна.

- Быстрая настройка поможет сэкономить время.

Основные выводы

- Выберите станок , соответствующий объему ваших потребностей в производстве. Убедитесь, что он отвечает вашим требованиям к пайке для достижения хороших результатов. - Выбирайте станки с низким энергопотреблением и интеллектуальным управлением. Это поможет вам сэкономить деньги и обеспечить безопасность. - Подумайте о мобильности, если вы работаете во многих местах. Более легкие станки легче перемещать для полевых работ. - Выбирайте станки с хорошими функциями безопасности для вашей безопасности. Это также способствует эффективной работе станка. - Покупайте у брендов, которые предоставляют качественную послепродажную поддержку. Это поможет вашему станку работать исправно в течение длительного времени.

Лучшие бренды индукционных паяльных аппаратов 2026 года

Серия Canroon CR

Серия Canroon CR использует интеллектуальные технологии в вашей мастерской. Эта машина выделяется на фоне современности 2026 года. Она оснащена передовой робототехникой , которая упрощает работу. Вы можете задавать режимы нагрева для каждой задачи. Система управления позволяет управлять машиной на расстоянии. В случае возникновения проблемы она быстро обнаружит и устранит её.

- Роботизированные манипуляторы помогают работать с большей точностью.

- Индивидуально разработанные планы отопления подходят для многих задач.

- Дистанционное управление и интеллектуальные решения экономят ваше время.

Совет: Если вам нужна универсальная и автоматизированная машина, попробуйте серию Canroon CR.

Система Ultraflex UBraze

Система Ultraflex UBraze экономит энергию и имеет интеллектуальное управление. Она использует быстрое цифровое управление, поэтому реагирует оперативно. Коэффициент преобразования энергии составляет более 95%. Коэффициент мощности лучше, чем 0,99, поэтому энергия расходуется впустую.

Вот что делает UBraze особенным:

В компактных системах Ultraflex SmartPower™ используется прямое цифровое ступенчатое управление Direct Digital Step™. Вы можете изменять выходную частоту для выполнения множества задач. Это обеспечивает больший контроль и помогает экономить энергию.

Портативные модели Fusion Inc.

Компания Fusion Inc. производит портативные индукционные паяльные аппараты для полевых работ и небольших мастерских. Эти аппараты легко переносить. Они хорошо работают и не занимают много места. Fusion Inc. станет лидером в 2026 году , потому что компания ориентируется на новые идеи и энергосбережение. Их оборудование помогает работать быстрее и потреблять меньше электроэнергии.

- Легкая конструкция облегчает перемещение.

- Надежный результат для многих видов пайки.

- Широкий выбор продукции и новые технологии.

Примечание: Если вам нужна машина для ремонта или выполнения выездных работ, портативные модели Fusion Inc. — хороший выбор.

Высокоэффективные блоки Radyne

Высокоэффективные установки Radyne помогут вам сэкономить деньги и работать быстрее . Эти машины экономно расходуют энергию. Цифровое управление обеспечивает более эффективное ведение производства. Компактная конструкция позволяет использовать их в робототехнике и автоматизированных системах. Большая удельная мощность означает большую производительность от небольшой машины.

Регулируемые силовые машины Siemens

Регулируемые сварочные аппараты Siemens подходят для множества видов пайки. Они позволяют очень точно контролировать температуру. Широкий диапазон частот (30-80 кГц) дает возможность работать с различными материалами. Автоматическая защита обеспечивает безопасность и продлевает срок службы аппарата.

Если вам нужен станок, который может адаптироваться к вашим потребностям, Siemens предоставит вам инструменты для любой паяльной работы.

Выбрав подходящий индукционный паяльник от этих производителей, вы получите интеллектуальное управление, экономию энергии и гибкость. Вы сможете работать эффективнее и тратить меньше, если выберете модель, соответствующую вашим потребностям.

Что такое индукционный паяльный аппарат?

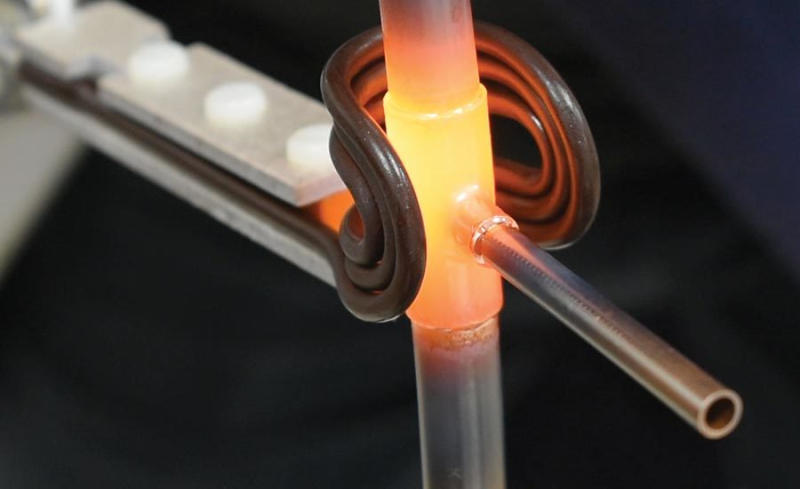

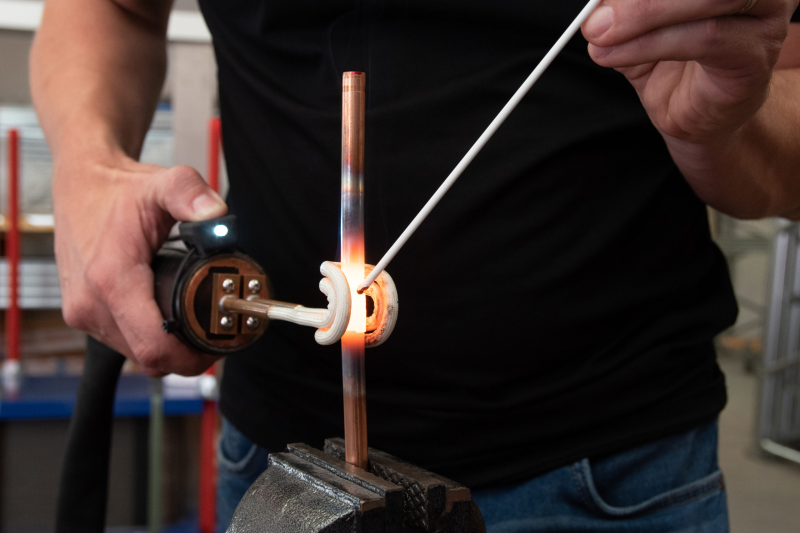

Как работает индукционная пайка

Индукционный паяльный аппарат позволяет быстро соединять металлические детали. Он использует сильное магнитное поле для нагрева металла. Тепло расплавляет припой. Расплавленный металл заполняет место соединения и склеивает детали. При этом не требуется использовать пламя или прикасаться к деталям. Это делает процесс более безопасным и точным.

Каждый индукционный паяльник имеет специальные детали, обеспечивающие его эффективную работу. В таблице представлен перечень компонентов современной системы:

Эти станки обеспечивают прочные, воспроизводимые и качественные соединения каждый раз. Интеллектуальное управление и функции безопасности помогают избежать ошибок и обеспечить безопасность всех участников процесса.

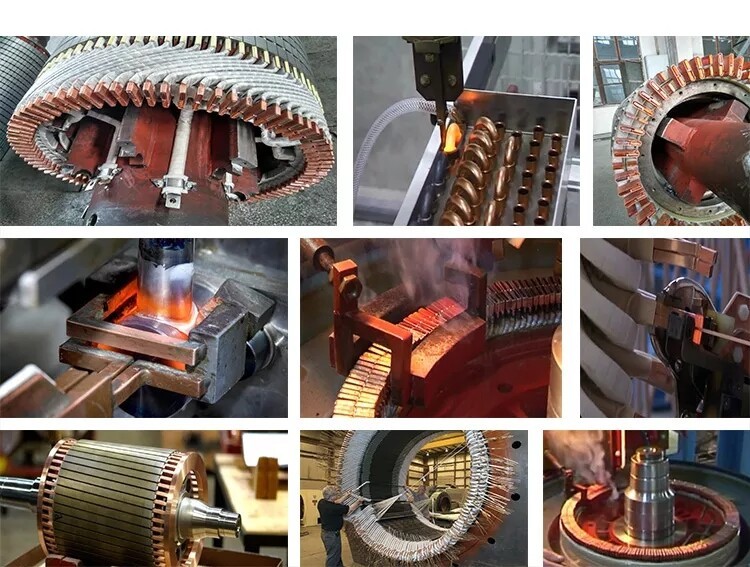

Ключевые области применения в 2026 году

В 2026 году во многих отраслях промышленности используются индукционные паяльные аппараты. Эти аппараты помогают работать быстрее и экономить энергию. Они позволяют соединять различные виды металлов для выполнения разных задач. Вот некоторые основные области применения :

Эти машины можно использовать для сборки электромобилей или изготовления медицинского оборудования. Если вы хотите преуспеть в своей области, вам понадобится подходящий индукционный паяльный аппарат.

Почему стоит выбрать индукционные паяльные аппараты в 2026 году?

Тенденции в отрасли

Производство сильно меняется в 2026 году. Компании стремятся к более экологичным и интеллектуальным машинам. Выбрав индукционный паяльный аппарат , вы сможете идти в ногу с этими изменениями. Вот почему новые тенденции делают эти машины хорошим выбором:

Приобретая индукционный паяльный аппарат, вы демонстрируете клиентам и партнерам свою заботу о будущем.

Преимущества в плане эффективности и охраны окружающей среды

Вы хотите экономить энергию и помогать планете. Индукционные паяльные аппараты позволяют делать и то, и другое. Вот как они упрощают и делают вашу работу экологичнее:

- Вы нагреваете только тот металл, который вам необходим, поэтому расходуете меньше энергии и быстрее завершаете работу.

- Вы не используете открытый огонь и не сжигаете топливо, поэтому не выделяете вредных газов и дыма.

- Вы используете меньше материала, потому что машина нагревает материал бережно и образует меньше отходов.

- Вы получаете цифровые элементы управления, которые позволяют отслеживать потребление энергии и подключаться к экологически чистым источникам энергии.

- Вы платите меньше за энергию и загрязняете окружающую среду меньше .

- Вы помогаете поддерживать чистоту воздуха, потому что эти машины производят меньше загрязняющих веществ, чем старые методы.

Если вы хотите сэкономить деньги, соблюдать новые правила и показать, что вам небезразлична чистота окружающей среды, выбирайте индукционный паяльник.

Сравнение моделей индукционных паяльных аппаратов

Таблица характеристик и цен

Вы хотите тратить деньги с умом. Правильно подобранная машина обеспечит вам мощность и безопасность. Она также будет обладать интеллектуальными функциями. Взгляните на эту таблицу, чтобы увидеть, как сравниваются лучшие машины в 2026 году:

Некоторые станки стоят дешевле. Другие стоят дороже, потому что имеют дополнительные функции. Большинство станков обеспечивают безопасность и работают с различными материалами.

Производительность и надежность

Вам нужна машина, которая будет работать безотказно каждый раз, когда вы ею пользуетесь. Высококачественные модели, такие как JL-25KW, могут работать весь день. Вам не нужно их останавливать. Автоматические системы помогают получать одинаковые результаты каждый раз. В новых машинах используется интеллектуальное управление для поддержания стабильной температуры. Это означает, что вы расходуете меньше материала и получаете более качественные швы. Большинство машин оснащены мощными системами охлаждения. Это помогает вашей машине служить дольше и оставаться безопасной.

Удобство использования и поддержка пользователей

Вам нужна машина, простая в использовании. Многие машины имеют простое управление и понятные экраны. Вы можете быстро настраивать задачи и быстро запускать оборудование. Если вам понадобится помощь, ведущие бренды обеспечат вам качественную поддержку. Вы получите руководства, видеоролики и оперативную помощь от экспертов. Хорошая поддержка означает, что вы тратите меньше времени и зарабатываете больше денег.

Выберите индукционный паяльник, соответствующий вашим потребностям. Убедитесь, что он обладает интеллектуальными функциями и отличной поддержкой. Вы будете работать быстрее, безопаснее и увереннее.

Ключевые особенности, которые следует учитывать.

Мощность и выходная мощность

Вам нужна машина, подходящая по объему для вашей работы. Мощность важна для скорости и качества. В 2026 году существует множество вариантов мощности. Разные уровни мощности подходят для разных задач.

Выберите станок с достаточной мощностью для выполнения самых сложных задач. Большая мощность обеспечивает более быстрый нагрев и более прочные соединения.

Портативность

На работе или в небольшой мастерской вам может понадобиться перемещать свой станок. Портативные станки позволяют выполнять работу в любом месте . Вот почему портативность полезна:

- Портативные системы, такие как ENRX Minac, хорошо подходят для использования на объекте.

- Почти половина всех продаваемых машин — портативные, поэтому они нравятся многим людям.

- С помощью газовой горелки можно выполнять работу гораздо быстрее, чем при использовании старых методов.

- Небольшие машины помещаются в ограниченном пространстве и упрощают ремонт.

- Мобильные ремонтные бригады отлично подходят для ремонта автомобилей и устранения неисправностей на месте.

Если вам нужно работать быстро и легко перемещать оборудование, выбирайте портативный станок.

Автоматизация и интеллектуальное управление

Вы хотите работать эффективнее и экономить время. Новые машины обладают интеллектуальными функциями. В 2026 году вы получите мониторинг через Интернет вещей (IoT), данные в реальном времени и интеллектуальное техническое обслуживание. Эти функции помогут вам избежать остановок в работе. Удобные экраны позволяют быстро настраивать задания. Системы безопасности, такие как световые башни и ограждения, обеспечивают вашу защиту. Для работы с некоторыми машинами достаточно одного или двух человек.

Совместимость материалов

Для получения прочных соединений необходимо использовать правильные металлы . Не все металлы хорошо подходят для индукционной пайки. На некоторых металлах образуются оксидные слои, препятствующие образованию соединений. Если вы выберете правильные основные и присадочные металлы, ваши соединения прослужат дольше. Для достижения лучших результатов избегайте очень реактивных или сложных сплавов.

Безопасность

Вы хотите работать в безопасности. Лучшие машины оснащены надежными средствами безопасности:

Системы охлаждения

Вы хотите, чтобы ваша техника служила долго. Системы охлаждения помогают ей работать исправно. Водяное охлаждение лучше всего подходит для поддержания низкой температуры и правильной работы. Оно поддерживает стабильную температуру и предотвращает повреждения. Воздушное охлаждение менее эффективно и может привести к более быстрому износу техники. Водяное охлаждение помогает вашей технике прослужить дольше без проблем .

Выберите индукционный паяльник с подходящими характеристиками. Вы получите лучшие результаты, обеспечите безопасность, и ваш прибор прослужит дольше.

Выбор подходящего индукционного паяльного аппарата

Соответствие применению и отрасли

Вам нужен станок, соответствующий вашей работе. Начните с анализа вашей отрасли и задач, которые вы выполняете каждый день. Некоторые станки лучше подходят для мелких деталей, в то время как другие обрабатывают крупные. Современные решения для индукционного нагрева предлагают гибкие выходные цепи и адаптивные источники питания . Эти функции позволяют настраивать станок для различных металлов и форм. Вы получаете больший контроль и лучшие результаты. Мощные и низкочастотные системы помогут вам достичь ваших целей, независимо от того, занимаетесь ли вы производством автомобилей, ремонтом инструментов или изготовлением электроники. Правильно подобранный станок повысит скорость работы и сократит количество ошибок.

Совет: Составьте список основных задач. Подберите для каждой задачи подходящий станок, который сможет выполнить её без труда.

Бюджет и рентабельность инвестиций

Вы хотите тратить деньги с умом. Не смотрите только на ценник. Подумайте о том, сколько будет стоить эксплуатация оборудования и сколько оно вам принесет прибыли. Хороший индукционный паяльник экономит энергию и уменьшает количество брака. Вы получаете больше качественных деталей и меньше отходов. Это означает, что со временем вы зарабатываете больше денег. Проверьте, как быстро работает оборудование и как часто вам нужно его ремонтировать. Если вы выберете модель, которая хорошо работает, вы получите лучшую отдачу от своих инвестиций . Качество и скорость имеют такое же значение, как и цена.

Послепродажная поддержка

Когда что-то идёт не так, вам нужна помощь. Хорошие бренды предлагают качественную послепродажную поддержку. Ищите компании, которые предоставляют обучение, руководства и быстрые ответы на ваши вопросы. Некоторые бренды предлагают удалённую помощь или отправляют экспертов на ваш объект. Такая поддержка позволяет вашей технике работать бесперебойно, а вашей работе — оставаться в рамках графика. Вы экономите время и избегаете длительных задержек. Выбирайте бренд, который будет поддерживать вас и после покупки.

Примечание: Надежная поддержка означает меньше стресса и больше успеха для вашего бизнеса.

Рекомендации пользователей

Для выездных техников

Вам нужна машина, которая будет работать где угодно. Возможность перемещать её и надёжность очень важны. Вы хотите быстро закончить работу и перейти к следующему этапу. Многие специалисты по пайке в 2026 году выбирают небольшие и надёжные индукционные паяльные системы. Эти машины прочные и удобны для переноски. Вот несколько лучших вариантов для вас:

Совет: если вам нужно работать в ограниченном пространстве или на крупной технике на открытом воздухе, выбирайте ручную или портативную систему.

Для мастер-классов

Вам нужен станок, который идеально впишется в вашу загруженную мастерскую. Быстрая работа, выполнение одной и той же задачи каждый раз и простая настройка помогут вам сделать больше. Люди предпочитают индукционные паяльные аппараты, которые быстро нагреваются и вписываются в ваш рабочий план. Цифровое управление упрощает настройку. Вы можете рассчитывать на то, что эти аппараты будут давать одинаковые результаты каждый раз.

- Быстрый нагрев экономит ваше время при выполнении любой работы.

- Цифровые экраны упрощают настройку даже для новых сотрудников.

- Эти машины идеально вписываются в окружающую среду, поэтому вам не нужно менять свой рабочий процесс.

Однако есть некоторые моменты, на которые следует обратить внимание. Некоторые говорят, что служба поддержки клиентов и руководства не всегда хороши. Проблемы с системой охлаждения могут остановить работу. Также может быть сложно найти запчасти для малоизвестных марок.

Примечание: Перед покупкой всегда проверяйте пространство вашего цеха и циркуляцию воздуха. Оборудование может перегреваться, если циркуляция воздуха недостаточна.

Для универсальных нужд

Вам нужна одна машина, способная выполнять множество задач. Возможность использовать её для разных целей и достаточная мощность помогут вам справиться с любой пайкой. В 2026 году, по мнению пользователей, серия SOLO UBraze хорошо подходит для работ, требующих перемещения, серия SOLO RoboBraze — для различных видов работ, а серия SOLO Dragon 24 — для больших объёмов работ. Модели EASYHEAT и EKOHEAT также отлично работают.

- Серия SOLO UBraze: прочная и легко перемещаемая, подходит для труднодоступных мест.

- Серия SOLO RoboBraze: подходит для выполнения множества работ по пайке.

- SOLO Dragon 24 Series: Лучший выбор для крупных деталей и узлов.

Если вы хотите расширить свой бизнес и попробовать себя в новых видах работ, выберите универсальный индукционный паяльный аппарат.

Вы хотите, чтобы ваша работа получалась превосходной. Лучшие индукционные паяльные аппараты 2026 года вам в этом очень помогут. Они потребляют меньше энергии , поэтому вы экономите деньги. Вы можете выполнять свою работу намного быстрее. Эти аппараты обеспечивают одинаково хорошие результаты каждый раз. Они также помогают поддерживать чистоту и безопасность в вашей мастерской. Поскольку они нагреваются без прямого контакта, ваши детали остаются чистыми и не изнашиваются.

Выберите станок, который соответствует вашим задачам и бюджету. Обратите внимание на такие характеристики, как интеллектуальное управление, точность и специальные функции. Canroon и другие ведущие бренды производят надежные станки , готовые к будущему.

Изучите таблицу выше, прислушайтесь к советам экспертов и задавайте вопросы, если вам нужна помощь. Таким образом, вы выберете подходящее оборудование для своего бизнеса.

Часто задаваемые вопросы

Чем индукционная пайка лучше, чем пайка пламенем?

Вы получаете более быстрый нагрев, лучший контроль и более безопасную работу. Индукционная пайка потребляет меньше энергии. Вы избегаете открытого огня, поэтому ваша мастерская остается чище. Вы также получаете более прочные и надежные соединения.

Как выбрать оптимальный уровень мощности для моего устройства?

Проверьте размер обрабатываемой детали и тип металла. Для мелких деталей выбирайте меньшую мощность. Для толстых или крупных деталей выбирайте большую мощность. Если вам нужна помощь, обратитесь за советом к поставщику.

Можно ли использовать один станок для обработки разных металлов?

Да! Многие лучшие станки позволяют настраивать параметры для работы с медью, сталью, латунью и другими материалами. Это обеспечивает гибкость при выполнении самых разных задач. Для достижения наилучших результатов всегда сверяйтесь с инструкцией по эксплуатации.

Требуется ли специальное обучение для работы с индукционными паяльными аппаратами?

Вам не потребуется много обучения. Большинство машин имеют простое управление и понятные экраны. Вы быстро освоите материал. Если вы хотите работать безопаснее и эффективнее, запросите демонстрацию или обучающий семинар.

Предыдущий:

Следующий:

Подписаться на обновления