Если вам нужен лучший электромагнитный индукционный нагреватель для работы в 2025 году, обратите внимание на ведущие модели. Вам нужен нагреватель, который будет работать хорошо, безопасно и надёжно каждый день. Всё больше людей сейчас ищут решения на основе электромагнитных индукционных нагревателей. Эта потребность наблюдается во многих отраслях. Объём рынка к 2025 году превысит 11,66 млрд долларов США . Новые технологии в области электромагнитных индукционных нагревателей открывают новые горизонты.

Рынок будет расти на 5,2% каждый год до 2032 года.

Рынок систем индукционного нагрева в 2025 году оценивается в 0,728 млрд долларов США.

Профессионалы высоко оценивают продукцию электромагнитных индукционных нагревателей:

С каждым годом всё больше людей хотят использовать электромагнитные индукционные нагреватели. Необходимо идти в ногу со временем и выбирать оптимальный продукт для своей работы.

Ключевые выводы

Электромагнитные индукционные нагреватели становятся всё более популярными. К 2025 году объём рынка может превысить 11,66 млрд долларов США. Выберите нагреватель, который соответствует вашим рабочим потребностям.

Индукционный нагрев имеет множество преимуществ. Он экономит энергию, безопасен и очень точен. Благодаря этим качествам он отлично подходит для использования на производстве.

При выборе индукционного нагревателя обратите внимание на выходную мощность, частоту и конструкцию катушки. Убедитесь, что он соответствует вашим задачам.

Такие топовые продукты, как Mini-Ductor® Venom® и Solary Magnetic Induction Heater, ценятся за скорость и безопасность. Они отлично подходят для самых разных задач.

Перед покупкой всегда проверяйте гарантию и условия поддержки. Хорошая гарантия сбережёт ваши деньги и поможет вам бережно обращаться с оборудованием.

Технология электромагнитного индукционного нагревателя

Как работает индукционный нагрев

Вам может быть интересно, как работает электромагнитный индукционный нагреватель. Сначала вы помещаете внутрь катушки металл, например, сталь. Катушка использует электричество для создания магнитного поля. Это поле вызывает вихревые токи в металле. Металл сопротивляется этим токам, и это выделяет тепло. Тепло быстро доходит до нужного места.

Вот что происходит в системе:

Тепло возникает из-за потерь на вихревые токи и гистерезис в металлах.

Частота источника питания влияет на количество получаемого тепла и на глубину его проникновения.

Второй закон Фарадея объясняет, как магнитное поле создает электричество в металле.

Сопротивление металла приводит к его нагреванию при прохождении через него тока.

Вы можете очень хорошо контролировать нагрев, что помогает при закалке или отпуске деталей.

Индукционная технология позволяет нагревать только нужную область. Вы не тратите энергию на обогрев всей площади. Именно поэтому технология электромагнитных индукционных нагревателей популярна на заводах и в мастерских.

Преимущества для профессионалов

Если вы работаете с промышленным нагревом, вам нужны инструменты, экономящие время и энергию. Технология электромагнитного индукционного нагрева имеет множество преимуществ по сравнению со старыми методами. Вы получаете более высокую эффективность, большую безопасность и более чистые результаты.

Ознакомьтесь с этой таблицей, чтобы узнать, почему профессионалы выбирают системы индукционного нагрева:

Вы получаете отопление, которое экономит энергию и помогает вам достигать своих целей. Системы индукционного нагрева также заботятся об окружающей среде. Вы можете быть уверены, что технология электромагнитного индукционного нагрева будет эффективно работать в сложных условиях. Если вы хотите работать быстрее и эффективнее в своих проектах, индукционный нагрев — отличный выбор.

Тенденции рынка электромагнитных индукционных нагревателей

Рост рынка и прогноз

Рынок электромагнитных индукционных нагревателей растёт с каждым годом. Всё больше отраслей промышленности ищут более эффективные способы обогрева. Это можно увидеть на примере заводов, автомастерских и технологических компаний. Рынок этих нагревателей в 2025 году выглядит перспективным. Вот несколько важных фактов об этом росте:

Мировой рынок электромагнитных индукционных нагревателей значительно вырастет в период с 2025 по 2031 год .

Темпы роста останутся высокими, что свидетельствует о росте рынка.

Все больше компаний используют индукционный нагрев, поскольку он экономит энергию и работает быстро.

Рынок продолжает расти, поскольку новые отрасли промышленности начинают использовать эти обогреватели.

Спрос на эти обогреватели будет расти по мере совершенствования технологий.

Если вы посмотрите на разные места, вы заметите некоторые различия на рынке:

Рынок растёт во всех регионах. Азиатско-Тихоокеанский регион является крупнейшим, но США и Европа также демонстрируют значительный рост.

Ключевые факторы в 2025 году

Вы можете спросить, почему рынок растёт так быстро. Причин этому множество. Во-первых, компании хотят экономить энергию и тратить меньше денег . Индукционный нагрев потребляет меньше энергии и обеспечивает больший контроль. Это помогает людям работать быстрее и безопаснее. Рынок также растёт, поскольку промышленность стремится к большей чистоте и экологичности. Индукционные нагреватели не дымят и не выделяют избыточное тепло, тем самым помогая планете.

Существует также больше правил экономии энергии . Эти правила побуждают компании использовать более совершенные системы отопления . Рынок растёт по мере того, как компании следуют этим правилам. Новые технологии, такие как усовершенствованное управление и автоматизация, делают индукционный нагрев ещё более популярным. Вы получаете более быстрый нагрев, меньше отходов и лучшие результаты.

Рынок продолжает расти, поскольку людям нужны более безопасные и чистые способы нагрева металла. Если вы работаете со сталью, автомобилями или любым другим оборудованием, требующим нагрева, с каждым годом вы будете видеть всё больше индукционных нагревателей. Тенденции показывают, что эта технология не исчезнет.

Лучшие электромагнитные индукционные нагреватели

Вам нужен лучший электромагнитный индукционный нагреватель для вашей работы? Давайте рассмотрим лучшие модели, которые профессионалы используют в 2025 году. Каждая модель подходит для разных задач. Вы найдете тот, который соответствует вашим потребностям. Неважно, работаете ли вы в магазине, на заводе или на улице.

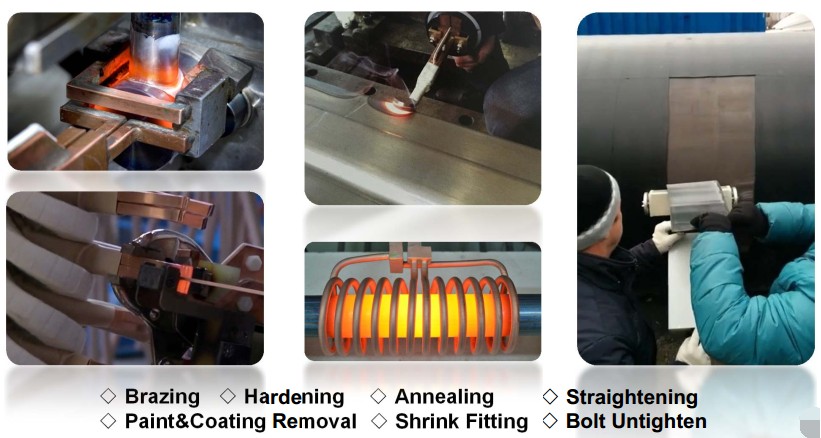

Серия Canroon CR2000

Если вам нужны мощность и контроль, обратите внимание на серию Canroon CR2000 . Мы предлагаем широкий выбор моделей. Вы можете выбрать электромагнитный индукционный нагреватель, подходящий под размер детали и тип выполняемой работы. Серия CR использует передовой индукционный нагрев. Он обеспечивает быстрые и точные результаты. Его можно использовать для закалки, пайки или термоусадки.

Вот краткий обзор технических характеристик:

Интеллектуальное управление с ПИД-регулятором температуры в замкнутом контуре. Вы можете переключать режимы для разных обрабатываемых деталей. Серия CR оснащена изолирующим трансформатором для обеспечения безопасности. Вам не нужно беспокоиться об открытом огне или неприятных испарениях. Конструкция с воздушным охлаждением обеспечивает бесперебойную работу даже в сложных условиях.

Плюсы:

Множество вариантов мощности для любой заготовки

Быстрый и точный индукционный нагрев

Модульная и экологичная конструкция

Хорошо работает в суровых условиях

Минусы:

Тяжелые модели трудно перемещать

Дополнительные функции стоят дороже

Идеальные варианты использования:

Крупногабаритная закалка металла

Прецизионная пайка

Термоусадочная посадка для больших заготовок

Солнечный магнитно-индукционный нагреватель

Вам нужен инструмент, который быстро нагревает болты и гайки? Магнитно-индукционный нагреватель Solary отлично справляется с этой задачей. Вы можете использовать его для ремонта автомобилей, работы с механизмами и любых работ с застрявшими болтами. Этот электромагнитный индукционный нагреватель использует индукционный нагрев для расширения металла без использования огня.

В комплект входит алюминиевый ящик для инструментов и десять катушек. Вы можете выбрать катушку, подходящую для вашей заготовки. Встроенный вентилятор охлаждает электромагнитный индукционный нагреватель. Светодиодная подсветка помогает видеть заготовку в тёмных местах.

Плюсы:

Нагревает болты и гайки за 30 секунд

Безопасно вблизи легковоспламеняющихся материалов

Легко держать и использовать

Имеет много катушек для различных заготовок

Минусы:

Только для небольших заготовок

Не для крупных промышленных работ

Идеальные варианты использования:

Авторемонтные мастерские

Техническое обслуживание машин

Удаление ржавых болтов из заготовок

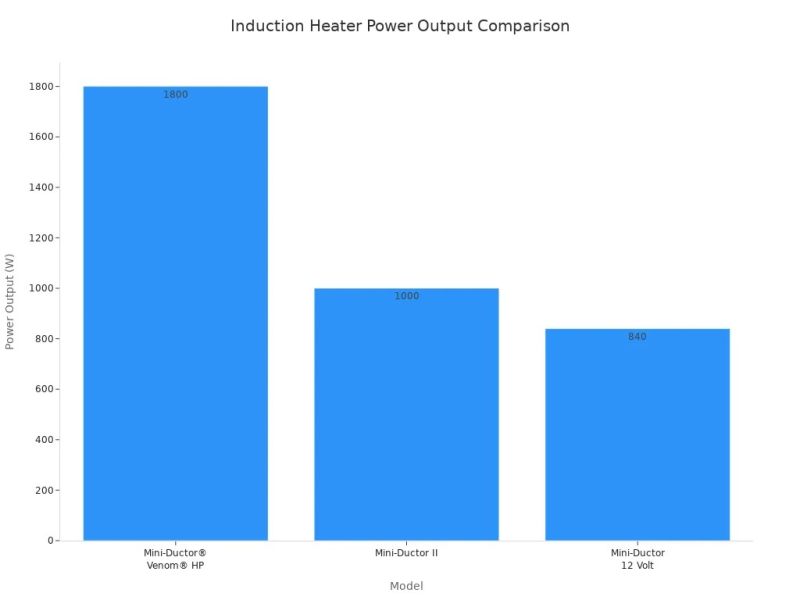

Mini-Ductor® Venom® HP

Вам нужен портативный электромагнитный индукционный нагреватель для сложных работ. Mini-Ductor® Venom® HP обеспечивает мощность индукционного нагрева 1800 Вт. С его помощью можно откручивать ржавые болты, гайки и другие металлические детали на обрабатываемой детали. Вам не нужен открытый огонь, что гарантирует безопасность.

Вы получаете такие функции, как светодиодная подсветка, индикатор использования и задержка отключения при возникновении ошибки. Рукоятку удобно держать долгое время. Поворотный фиксатор катушки позволяет быстро менять катушки для разных обрабатываемых деталей. Руководство пользователя доступно на нескольких языках.

Вы можете сократить трудозатраты до 75%

Вы можете сохранить детали, которые вы могли бы выбросить

Вы экономите деньги на расходных материалах

Этот электромагнитный индукционный нагреватель можно использовать для датчиков ABS, подшипников, выхлопных систем, ремней крепления топливного бака, деталей рулевого управления, болтов кузова грузовика и U-образных болтов. Он хорошо подходит для деталей, находящихся рядом с резиной или пластиком.

Плюсы:

Портативный и легкий

Нагревает и ослабляет болты без пламени

Подходит для деталей, находящихся рядом с легковоспламеняющимися материалами.

Сокращение трудозатрат и экономия деталей

Минусы:

Не заменяет горелку для всех работ.

Только для небольших заготовок

Идеальные варианты использования:

Ремонт автомобилей

Спасение ржавых деталей

Работа вблизи топливных баков или пластика

Индукционная серия EFD Minac

Вам нужна гибкость и интеллектуальное управление? Серия EFD Induction Minac — это небольшой электромагнитный индукционный нагреватель с сенсорным экраном. Вы можете использовать два выхода мощности для двух обрабатываемых деталей одновременно. Пистолетная рукоятка облегчает индукционную пайку.

Этот электромагнитный индукционный нагреватель можно использовать для термообработки, пайки, термоусадки, закалки, вулканизации и правки. Он обеспечивает гибкость при обработке различных деталей.

Плюсы:

Маленький и простой в использовании

Нагревает две заготовки одновременно

Сенсорное управление

Работает со многими типами катушек

Минусы:

Стоит дороже базовых моделей

Требуется обучение для использования расширенных функций

Идеальные варианты использования:

Промышленные мастерские

Соединение и закалка металлов

Работы с большим количеством заготовок

Амбрел EASYHEAT

Вам нужен надежный электромагнитный индукционный нагреватель для небольших и средних деталей. Ambrell EASYHEAT обеспечивает мощность индукционного нагрева до 2,4 кВт. Его можно использовать для закалки, термоштамповки, горячей штамповки, левитационной плавки и других задач.

Этот электромагнитный индукционный нагреватель можно использовать для самых разных задач. Он отлично подходит для нагрева, закалки, термоштамповки, горячей штамповки, левитационной плавки, испытаний материалов, производства медицинских приборов, плавки, сварки металла со стеклом, упаковки, термоусадки, пайки и нагрева токоприемников.

Плюсы:

Надежный и стабильный индукционный нагрев

Подходит для многих типов заготовок

Подходит для небольших и средних работ

Минусы:

Не для очень больших заготовок

Меньшая мощность, чем у мощных моделей

Идеальные варианты использования:

Производство электроники

Производство медицинских изделий

Мелкие работы по металлообработке

Совет: При выборе электромагнитного индукционного нагревателя учитывайте размер обрабатываемой детали, тип работы и требования безопасности. Каждая модель имеет различную мощность для нагрева конкретной детали.

Сравнительная таблица продуктов

Вам необходимо выбрать подходящий электромагнитный индукционный нагреватель для вашей задачи. Полезно сравнить лучшие модели. В этой таблице представлены данные по мощности, эффективности и сроку службы каждого нагревателя:

Совет: Всегда проверяйте класс эффективности. Большинство топовых моделей преобразуют не менее 90% энергии в тепло. Это означает, что вы тратите меньше энергии и экономите деньги.

Вот несколько моментов, которые следует учитывать при сравнении продуктов:

Выходная мощность: большие цифры означают более быстрый нагрев при больших объемах работ.

Рабочий цикл: если он работает постоянно, вы сможете работать дольше.

Гарантия: большинство брендов дают 24 месяца, поэтому вы можете чувствовать себя в безопасности.

Надежность: высокое качество и низкий уровень отказов означают меньшее количество исправлений.

Срок службы: многие обогреватели служат до 10 лет, если за ними ухаживать.

Дополнительную информацию о ремонте продукции и гарантии можно найти на сайте The Inductor .

Выбирая эти обогреватели, подумайте, что вам нужно для работы. Вам нужна большая мощность или более лёгкий инструмент? Вам нужна длительная гарантия или простота обслуживания? Выбор правильного обогревателя поможет вам работать быстрее и оставаться в безопасности каждый день.

Особенности индукционного нагрева

Мощность и эффективность

Выбор электромагнитного индукционного нагревателя подразумевает правильный выбор мощности. Выходная мощность показывает, насколько быстро вы можете нагревать предметы . Если вы работаете с большими металлическими деталями, вам потребуется больше мощности. Для небольших работ требуется меньше мощности. Наилучшие результаты достигаются при подборе мощности под ваши задачи.

Также следует учитывать частоту. Высокие частоты нагревают мелкие детали быстро. Низкие частоты нагревают более глубоко. Конструкция спирали влияет на эффективность работы вашего нагревателя. Некоторые спирали нагреваются быстро, другие — более равномерно. Системы охлаждения продлевают срок службы нагревателя. Воздушное или водяное охлаждение обеспечивает его безопасность и стабильность.

Совет: Всегда обращайте внимание на систему управления. Качественные системы позволяют регулировать температуру. Вы можете наблюдать за процессом и каждый раз получать одинаковые результаты.

Безопасность и надежность

Вы хотите, чтобы ваш электромагнитный индукционный нагреватель был безопасным и работал исправно. Индукционный нагрев не использует открытый огонь, поэтому он безопаснее. Большинство нагревателей оснащены встроенными функциями безопасности, включая защиту от перегрева, автоматическое отключение и сигнализацию. Вы можете без опасений работать рядом с легковоспламеняющимися предметами.

Надёжность означает, что ваш обогреватель работает каждый день. Обратите внимание на надёжную систему охлаждения и прочные детали. Многие бренды предоставляют гарантию. Это поможет, если что-то сломается.

Вот некоторые характеристики безопасности и надежности, на которые следует обратить внимание:

Защита от перегрева

Автоматическое отключение

Сигнализации о неисправностях

Мощные системы охлаждения

Длительные гарантийные сроки

Портативность и дизайн

Иногда вам нужно переместить электромагнитный индукционный нагреватель. Портативность облегчает работу. Более лёгкие модели подходят для работы в небольших помещениях или на объекте. Некоторые нагреватели оснащены ручками или колёсами. Вы можете переносить или катить их куда угодно.

Дизайн тоже важен. Хороший обогреватель должен иметь легко читаемый дисплей. Управление должно быть простым, а держать обогреватель удобно. Некоторые обогреватели поставляются с ящиками для инструментов или кейсами. Это обеспечит сохранность ваших спиралей и деталей.

Выбирая индукционный нагреватель, подумайте о том, как вы будете его использовать. Правильная конструкция экономит ваше время и силы каждый день.

Как выбрать электромагнитный индукционный нагреватель

Потребности приложения

Вам необходимо выбрать подходящий электромагнитный индукционный нагреватель для вашей работы. Прежде всего, подумайте, для чего вы будете его использовать. Какой металл вам нужно нагревать? Какого размера ваши заготовки? Для некоторых задач требуется большая мощность. Для других задач нужен инструмент, который вы сможете носить с собой. Убедитесь, что нагреватель соответствует вашим ежедневным задачам.

Вот о чем следует подумать перед покупкой:

Определитесь, для чего вы будете его использовать. Если вы работаете со сталью или чугуном, убедитесь, что электромагнитный индукционный нагреватель способен нагревать эти металлы.

Проверьте, сколько у него мощности. Для больших работ требуется больше мощности. Для небольших ремонтов нужно меньше.

Обратите внимание на частоту. Тонкий металл быстро нагревается при высокой частоте. Толстому металлу требуется более низкая частота для полного прогрева.

Подумайте о форме спирали. Правильная форма спирали способствует равномерному нагреву заготовки.

Решите, нужно ли вам его перемещать. Некоторые модели электромагнитных индукционных нагревателей легко переносить. Другие же можно ставить на одно место для выполнения больших объёмов работ.

Охлаждение важно. Если в вашем магазине жарко, выберите обогреватель с хорошим охлаждением.

Вам нужно, чтобы ваш электромагнитный индукционный нагреватель работал быстро и не тратил энергию впустую. Индукционный нагреватель быстрее, чем старые методы нагрева с использованием катушек. Он потребляет меньше электроэнергии и поддерживает чистоту в цехе. Правильный выбор размера позволит вам сэкономить энергию. Слишком большой нагреватель расходует электроэнергию впустую. Маленький нагреватель увеличит время ожидания. Всегда подбирайте электромагнитный индукционный нагреватель под ваши задачи для достижения наилучших результатов.

Гарантия и поддержка

Гарантия и поддержка помогут вам чувствовать себя уверенно при покупке. Большинство производителей электромагнитных индукционных нагревателей предоставляют двухлетнюю гарантию . Она покрывает проблемы, возникшие при производстве изделия. Если вы обнаружите какую-либо неисправность, вы можете обратиться в службу поддержки в течение двух месяцев. Ремонт должен осуществляться в специализированных мастерских. После ремонта вы получите бесплатную оценку стоимости ремонта и полную проверку.

Вот краткий обзор распространенных вариантов гарантии:

Вы также можете получить помощь с ремонтом. Некоторые бренды позволяют отправлять нагреватель в ремонт и предоставляют формы для проверки гарантии. Качественная поддержка позволит вам дольше использовать электромагнитный индукционный нагреватель и меньше ждать ремонта. Если вы используете нагреватель ежедневно, надежная гарантия и поддержка помогут поддерживать его в рабочем состоянии.

Совет: Всегда читайте гарантию перед покупкой. Хорошая поддержка облегчит вашу работу и сэкономит ваши деньги.

В 2025 году вы сможете выбрать из множества хороших электромагнитных индукционных нагревателей. Такие бренды, как Canroon, Solary и Mini-Ductor®, известны своей прочностью, безопасностью и надёжностью. Важно выбрать нагреватель, соответствующий вашим потребностям. Сравнительная таблица и руководство по покупке помогут вам сделать правильный выбор.

Найдите обогреватели, которые потребляют меньше энергии и работают хорошо.

Выбирайте модели, имеющие хорошие сертификаты безопасности.

Выбирайте дизайн, который соответствует месту и стилю вашей работы.

Эксперты утверждают, что экономия энергии и забота о планете сейчас очень важны. Новые экологичные системы отопления помогут вам экономить и заботиться об окружающей среде.

Следите за новостями рынка. Купив подходящий индукционный нагреватель сейчас, вы будете готовы к будущему и сможете работать эффективнее.

Часто задаваемые вопросы

Какие металлы можно нагревать с помощью электромагнитного индукционного нагревателя?

Можно нагревать сталь, железо, медь и алюминий. Большинство индукционных нагревателей лучше всего работают с металлами с высоким электрическим сопротивлением. При использовании подходящей катушки можно нагревать изделия самых разных форм и размеров.

Как обеспечить безопасность индукционного нагревателя во время использования?

Всегда проверяйте обогреватель на перегрев. Используйте встроенные функции безопасности, такие как автоматическое отключение и сигнализация. Поддерживайте чистоту в помещении. Никогда не прикасайтесь к включённому змеевику. Если загорелся предупреждающий индикатор, остановите обогреватель и дайте ему остыть.

Совет: перед началом работы прочтите инструкцию. Безопасность превыше всего!

Можно ли использовать индукционные нагреватели для ремонта автомобилей?

Да, вы можете использовать индукционные нагреватели для откручивания ржавых болтов, гаек и других металлических деталей. Многие автомастерские используют портативные модели для быстрого ремонта. Это экономит время и позволяет избежать открытого огня.

Как выбрать правильную катушку для вашей работы?

Выберите катушку, соответствующую форме и размеру вашей заготовки. Для достижения наилучших результатов попробуйте разные катушки.

Предыдущий:

Следующий:

Подписаться на обновления