Вам понадобится лучшее оборудование для индукционного удаления покрытий с стали, чтобы соответствовать новым требованиям 2025 года. Индукционные технологии теперь работают быстрее и чище, чем раньше. Они также обеспечивают более точные результаты. Рынок растет и достигнет$2,3 миллиарда к 2025 году. Многие отрасли требуют эффективных, бесконтактных и надежных решений. Новые функции, такие как цифровое управление и интеграция с IoT, делают ваше оборудование более удобным в использовании. Эти функции также помогают выполнять больше работы. Выбор правильного индукционного инструмента для работы со сталью важен, так как сейчас доступно больше вариантов.

Ключевые выводы

Индукционные инструменты для удаления покрытийбыстрее и чище старых методов. Они помогают экономить время и энергию. Выбирайте лучший инструмент в зависимости от масштаба проекта и толщины покрытия. Это обеспечит наилучшие результаты. Ищите инструменты с цифровым управлением и удобной переноской. Эти функции делают работу проще и быстрее. Индукционные инструменты безопаснее и экологичнее. Они не создают пыли и не используют опасные химикаты. Учитывайте экономию на ремонте и эксплуатационных расходах при выборе оборудования для индукционного удаления покрытий.

Оборудование для индукционного удаления покрытий: Лучшие выборы

Система индукционного удаления покрытий Canroon

Система Canroon Induction Coating Removal Systemобеспечивает выдающуюся производительность и точный контроль для быстрого и безопасного удаления покрытий с стальных поверхностей. Она может сократить время работы до 75%, без использования вредных химикатов или расходных материалов, повышая безопасность и экологическую устойчивость. Благодаря универсальной конструкции питания со стандартным входом 2,200W и выходом до 2,000W, система Canroon предлагает широкую адаптируемость для различных применений в обработке стали. Сочетание высокой эффективности, широкой применимости в отраслях и экономичности делает ее идеальным решением для разнообразных задач удаления покрытий.

Индукционный инструмент ENRX Minac

Индукционный инструмент ENRX Minac используется в производственных условиях для удаления покрытий. Он может работать с покрытиями толщиной до 10 мм в режиме сканирования и 40 мм в точечном режиме. Инструмент работает от сети 480 В с периодическим потреблением около 40 кВт. Во время работы он создает минимальный шум и пыль.

Индукционный удалитель покрытий ProHeat Industrial

ProHeat — это индукционный блок для удаления покрытий, предназначенный для задач обработки стали. Он направлен на упрощение эксплуатации и снижение трудозатрат в соответствующих применениях.

Портативный индукционный удалитель покрытий SteelMaster

SteelMaster — это портативное устройство, подходящее для удаления покрытий в ограниченных пространствах. Оно разработано для легкого перемещения и установки, работает тихо и не создает пыли.

Каждое оборудование для индукционного удаления покрытий имеет свои преимущества. Выбирайте то, что соответствует вашему проекту и условиям работы.

Ключевые характеристики и спецификации

Мощность и эффективность

Вам нужен инструмент, который работает быстро и экономит энергию.Индукционный нагрев обеспечивает мгновенное тепло, поэтому вам не придется ждать. Тепло сильное и равномерное, что помогает быстро удалять покрытия. Большинство инструментов имеют цифровое управление. Вы можете установить температуру и мощность для вашей задачи. Это помогает получать хорошие результаты каждый раз. Индукционный нагрев использует меньше энергии, так как нагревает только нужные участки.

Поддерживаемые типы стали

Эти инструменты можно использовать на многих типах стали.В таблице ниже показано, какая сталь работает лучше всего и где есть ограничения:

Проверьте тип вашей стали перед началом работы. Это поможет избежать проблем и получить наилучшие результаты.

Портативность и удобство использования

Вам нужен инструмент, который легко перемещать и использовать. Многие системы индукционного нагрева легкие и портативные. Их можно использовать в мастерской или на рабочей площадке. Функции, такие как сменные катушки и цифровое управление, облегчают работу. Вы можете менять катушки для разных форм и размеров.В таблице ниже показано, что делает эти инструменты удобными:

Безопасность и соответствие

Вы хотите быть в безопасности во время работы. Инструменты индукционного нагрева имеют функции безопасности, такие как защита от перегрева и перегрузки. Некоторые инструменты также проверяют низкий расход воды. Эти функции помогают избежать аварий. Вам не нужны открытые пламя, поэтому рабочая зона безопаснее. Вы также создаете меньше пыли и дыма, что лучше для вашего здоровья.

Цена и ценность

Инструменты индукционного нагрева доступны в широком диапазоне цен, чтобы соответствовать разным потребностям и бюджетам. Например, Inductor® Pro-Max Fully Loaded (PM-200FL)стоит$3,719.00 и разработан как надежная система для требовательных промышленных применений.

Если вы ищете высокую производительность без высокой стоимости, Система индукционного удаления покрытий Canroonпредлагает отличный баланс возможностей и доступности. Она обеспечивает надежную мощность и эффективность по более доступной цене, позволяя достигать профессиональных результатов при меньшем бюджете.

При выборе системы учитывайте ваши конкретные потребности и ожидаемую ценность. Хотя премиальные модели имеют расширенные функции,Canroonдоказывает, что вам не всегда нужно тратить больше, чтобы получить необходимую производительность.

Методы удаления покрытий в сравнении

Индукция против традиционных методов

Существуют разные способы удаления покрытий со стали. Каждый способ работает по-своему и дает разные результаты. В таблице ниже показано, чем отличаютсяиндукция, абразивная очистка и химическое удаление:

Индукция особенна тем, что она быстрая и эффективна для твердых покрытий. Абразивная очистка занимает больше времени и создает много пыли. Химическое удаление может быть медленным и оставлять липкие остатки.

Повышение производительности и эффективности

Вы хотите завершать работы быстрее и не тратить энергию впустую.Индукционное удаление покрытий помогает в этом. Эти инструменты могут ускорить вашу работу до 90% по сравнению со старыми методами. Вы также используете примерно на 75% меньше энергии. Вам не нужно ждать, пока инструмент нагреется. Вы получаете тепло сразу и можете очищать больше стали за меньшее время. Это экономит деньги и позволяет выполнять больше задач каждый день.

Совет:Индукционное удаление покрытий почти не создает отходов или дыма. Вам не нужно беспокоиться о пыли или грязной воде.

Экологические и безопасностные преимущества

Вы хотите оставаться в безопасности и помогать планете.Индукционное удаление покрытий помогает в обоих случаях. Вы не используете химикаты или абразивный песок, поэтому не вдыхаете вредные пары или пыль. Процесс чистый и тихий. Вы можете работать в общественных местах без шума или беспорядка. Инструмент не нагревается снаружи, поэтому вы не обожжетесь. Вы также создаете меньше мусора, что делает уборку легкой и безопасной для всех.

Нет пыли в воздухе или токсичной грязи

Нет грязной воды или песка

Использование меньшего количества энергии лучше для земли

Безопасно использовать во многих местах, даже рядом с людьми

Вы получаете более чистый, безопасный и быстрый способ удаления покрытий со стали.

Подробные обзоры: Сбалансированная производительность и разумная ценность

Система индукционного удаления покрытий Canroon

Система Canroon разработана для надежного и высокопроизводительного удаления покрытий в широком диапазоне применений для стали. Она эффективно удаляет толстые покрытия с регулируемым нагревом и мощностью, адаптированными для каждого проекта. Встроенные защитные функции позволяют работать с уверенностью, а энергоэффективная конструкция устраняет необходимость в химикатах или абразивных материалах.

Сильные стороны:

Обеспечивает высокую мощность для быстрого завершения работ

Энергоэффективность и экологичность, без использования химикатов

Предоставляет точный контроль через удобные цифровые настройки

Включает защиту от перегрева и перегрузки для повышенной безопасности

Совместима с различными типами стали и состояниями поверхности

Высокая долговечность и низкие затраты на обслуживание снижают долгосрочные эксплуатационные расходы

Слабые стороны:

Некоторые расширенные функции могут потребовать начального обучения

Вес системы может быть менее подходящим для очень мелких или деликатных задач

Примечание: Canroon выделяется своей выдающейся долговечностью и минимальными потребностями в обслуживании, позволяя вам сосредоточиться на продуктивности, а не на уходе за инструментом.

Индукционный инструмент ENRX Minac

ENRX Minac способен на быстрое удаление покрытий и подходит для сред с доступом к сети 480 В. Он может обрабатывать толстые покрытия и разработан для тихой работы без образования пыли.

Рекомендации:

Требуется источник питания 480 В, что может ограничить гибкость на площадке

Более высокие первоначальные инвестиции по сравнению с некоторыми альтернативами

Индукционный удалитель покрытий ProHeat Industrial

ProHeat предлагает простое решение для базовых задач удаления покрытий со стали, с акцентом на простоту эксплуатации и снижение использования химикатов.

Рекомендации:

Отсутствуют расширенные цифровые управления, доступные в других системах

Портативность может быть ограничена в зависимости от потребностей рабочей площадки

Портативный индукционный удалитель покрытий SteelMaster

SteelMaster предлагает компактный и портативный дизайн, подходящий для ограниченных пространств или легких задач, где мобильность является приоритетом.

Рекомендации:

Выходная мощность ниже по сравнению с полноценными системами

Скорость удаления может снижаться на очень толстых покрытиях

Советы:

При выборе системы индукционного удаления покрытий учитывайте ваши конкретные требования проекта, условия площадки и бюджет. Система Canroon предлагает убедительный баланс мощности, контроля, безопасности и экономической эффективности, что делает ее идеальным выбором для пользователей, которые ищут профессиональную производительность без усложнения операций или чрезмерных первоначальных или долгосрочных затрат. Ее универсальность для различных типов стали и акцент на долговечность дополнительно поддерживают стабильную продуктивность в различных рабочих условиях.Выбор правильного оборудования

Оценка потребностей проекта

Сначала подумайте о масштабе вашего проекта. Некоторые инструменты для индукционного удаления покрытий лучше подходят для больших площадей. Другие хорошо работают в небольших или тесных пространствах. Если вам нужно удалять толстые покрытия со стали, вам нужен инструмент с высокой мощностью. Он также должен быстро удалять покрытия. Для небольших работ или детализации портативные системы очень полезны. Всегда выбирайте оборудование, соответствующее вашим задачам.

Соответствие оборудования типам стали

Разные типы и толщины стали требуют разных инструментов. Большинство индукционных систем работают с углеродистой и конструкционной сталью. Но некоторые покрытия и тонкие слои могут не подходить. В таблице ниже показано, какой инструмент лучше всего подходит для каждой задачи:

Проверьте тип вашей стали и толщину покрытия перед выбором инструмента. Это поможет избежать ошибок и получить хорошие результаты для вашей работы.

Бюджет и ценовые соображения

Вы хотите сэкономить деньги и получить хорошую ценность. Оборудование для индукционного удаления покрытий экономит деньги со временем. Вам не нужно покупать абразив или химикаты. Вы также создаете меньше отходов и снижаете затраты. Вот что следует учитывать:

Индукционный нагрев помогает вамбыстрее завершить удаление краски.

Вы снижаете риск пожара и травм работников.

Процесс соответствует новым правилам безопасности и экологии.

В таблице ниже показано, как индукционные инструменты помогают экономить деньги в разных задачах:

Вы также тратите меньше на ремонт и питание инструментов. Большинство устройств требуют проверки и очистки только раз в год. Некоторые системы могут проверять себя и сокращать обслуживание до 40%. В таблице ниже показано, как вы экономите деньги со временем:

Поддержка и гарантия

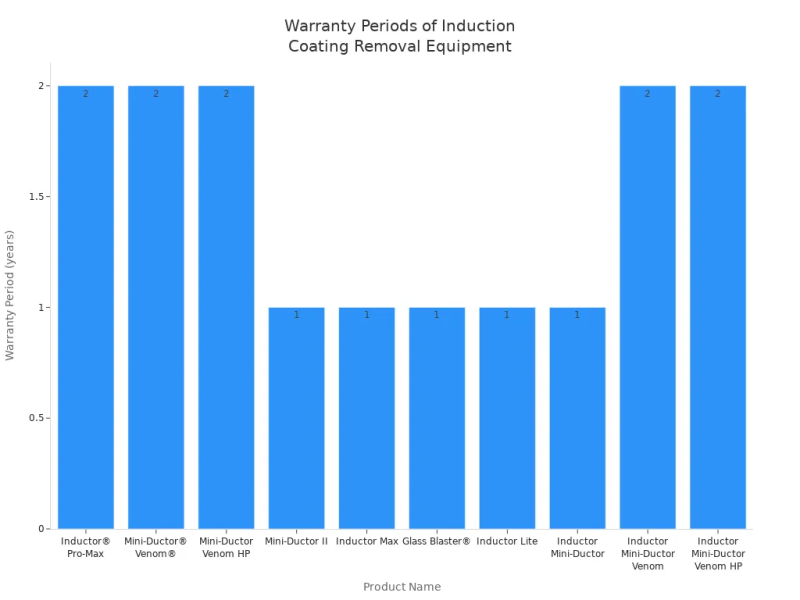

Ищите оборудование с хорошей поддержкой и гарантией. Лучшие бренды предлагают регистрацию продукта, ремонт и обучение. Большинство гарантий действуют один или два года. На диаграмме ниже показано, как долго действуют гарантии для популярных инструментов:

Вы чувствуете себя увереннее, выбирая оборудование с надежной поддержкой. Это помогает вашим инструментам служить дольше и хорошо работать во всех задачах.

Теперь вы видите, чем отличаются эти инструменты для индукционного удаления покрытий со стали. В таблице ниже приведены основные факты:

При выборе системы индукционного удаления покрытий учитывайте масштаб вашего проекта и ваши приоритеты в работе. Для универсального и экономически эффективного решения, подходящего для широкого спектра применений — от средних задач до требовательных промышленных проектов — система Canroon предлагает отличный баланс мощности, контроля и надежности. Она разработана для эффективного удаления различных типов покрытий и стальных поверхностей, что делает ее практичным и ценным выбором для большинства пользователей.

Если ваша работа постоянно связана с крупномасштабными, высокомощными операциями и у вас есть доступ к сети 480 В, ENRX Minac может быть настроен для таких условий. Для небольших или ограниченных пространств, где важна портативность, SteelMaster предоставляет компактный вариант.

Прежде чем принять решение, обязательно ознакомьтесь с доступной поддержкой, гарантией и сервисными предложениями каждого производителя. Вы также можете связаться с ними напрямую, чтобы обсудить ваши конкретные потребности — хороший поставщик поможет вам выбрать инструмент, который действительно соответствует вашим условиям работы и долгосрочным целям.

FAQ

Что делает индукционное удаление покрытий лучше традиционных методов?

Вы получаете более быстрое удаление покрытий с индукционными инструментами. Вам не нужны химикаты или абразивная очистка. Тепло воздействует только на покрытие. Это сохраняет стальную поверхность в безопасности. Вы завершаете процесс удаления с меньшим беспорядком и меньшим риском для здоровья.

Можно ли использовать индукционное удаление покрытий на любой стальной поверхности?

Вы можете использовать индукционное удаление покрытий на большинстве стальных поверхностей. Процесс лучше всего работает с углеродистой и конструкционной сталью. Тонкие покрытия или специальные поверхности могут работать не так хорошо. Всегда проверяйте поверхность и тип покрытия перед началом удаления.

Как подготовить поверхность для индукционного удаления покрытий?

Сначала очистите поверхность. Удалите рыхлую грязь или жир. Убедитесь, что покрытие сухое. Это помогает инструменту для удаления работать лучше. Чистая поверхность позволяет индукционному теплу достигать покрытия. Вы получаете более плавный процесс удаления и лучшие результаты.

Безопасно ли индукционное удаление покрытий для использования в помещении?

Вы можете использовать индукционное удаление покрытий в помещении. Процесс не создает пыли или дыма. Вам не нужны открытые пламя. Поверхность остается холодной, кроме покрытия. Вы сохраняете рабочую зону безопасной и чистой во время удаления.

Как понять, что удаление покрытия завершено?

Вы наблюдаете, как покрытие отделяется от поверхности. Инструмент для удаления нагревает покрытие до его отделения. Вы можете проверить поверхность скребком. Если покрытие легко снимается, удаление завершено. Всегда проверяйте всю поверхность на остатки покрытия.

Предыдущий:

Следующий:

Подписаться на обновления